Oil & Gas Containment

Tailored Solutions for Complex Oil & Gas Containment

Frac Pad Liners

Tank Liners

Drilling Mud Containment

Produced & Process Water Containment

Noise Abatement (MLV Add-On)

Stakeholder Benefits of E Squared Oil & Gas Containment Geomembranes

E Squared geomembranes are engineered for long-term performance in demanding oil and gas environments. Whether you’re designing, fabricating, installing, or operating a containment system, our materials are built to deliver superior protection, maintain compliance, and reduce environmental and financial risk.

For Civil Engineers

Our geomembranes are ASTM-tested and backed by reliable, published data, giving engineers, contractors, and owners the confidence to specify materials with proven performance. Every product is validated against industry standards to ensure consistency, durability, and compliance in critical oil and gas containment applications.

With decades of proven field performance, E Squared geomembranes have been trusted across oil and gas applications ranging from secondary containment basins to frac pit liners. Our track record demonstrates long-term durability, chemical resistance, and reliability in the toughest operating environments.

E Squared provides dedicated technical support for specifications and submittals, ensuring engineers and contractors have the documentation, data, and guidance needed to streamline project approval and meet regulatory requirements.

For Installers

E Squared offers panelized deliveries and factory-fit details designed to accelerate installation and minimize field labor. By reducing seaming and on-site adjustments, our geomembranes help contractors save time, lower costs, and keep projects on schedule.

Our geomembranes feature seams designed for efficient QA/QC, incorporating dual-track air channel testing to verify weld integrity in real time. This ensures faster, more reliable quality control in the field while reducing the risk of costly rework.

E Squared geomembranes are manufactured with consistent material weld windows, giving installers predictable, repeatable results in the field. This reliability streamlines installation, improves seam integrity, and ensures long-term performance under demanding oil and gas conditions.

For Fabricators

Ensures precision during prefabrication and reduces waste in cutting and welding processes.

Performs reliably in both manual and mechanized fabrication environments.

PVC for flexibility, EIA for rugged durability, and LLDPE for elongation and impact resistance.

For Project Owners

Geomembranes that resist tears, UV damage, and chemical breakdown reduce unplanned repairs.

Materials support compliance with environmental and wastewater regulations, minimizing potential fines or legal exposure.

Longer system life and fewer failures mean greater return on capital investments in wastewater infrastructure.

Solutions for your application.

Benefits

Overall Benefits of E Squared Geomembranes for Wastewater Applications

EIA (E Squared) geomembranes are an excellent choice for oil and gas containment applications, offering superior resistance to hydrocarbons, chemicals, and harsh environmental conditions.

Proven Field Track Record

E Squared geomembranes provide a high-performance solution for oil and gas containment across upstream, midstream, and downstream operations. As impermeable barriers, they protect against leakage, seepage, and contamination—safeguarding soil, groundwater, and surrounding ecosystems while supporting compliance with stringent environmental regulations.

Engineered for durability, hydrocarbon resistance, and adaptability, our geomembranes deliver consistent performance across applications such as secondary containment basins, produced water ponds, frac pits, and pipeline trench liners. Their ease of installation, proven field performance, and long service life reduce project risk and operational costs, making them a trusted choice for modern oil and gas containment systems.

Hydrocarbon & Chemical Resistance

Leak & Seepage Prevention

Adaptability to Site Conditions

Ease & Speed of Installation

Predictable Field Performance

Technical & Spec Support

Cost Efficiency & Risk Reduction

Regulatory Compliance & Environmental Protection

These benefits and features are crucial for key stakeholders such as project owners, civil engineers, fabricators, and installers, as they address concerns related to water quality, project durability, cost-effectiveness, and regulatory compliance.

Sub-Applications

Where E Squared Excels

E Squared geomembranes are purpose-engineered to deliver reliable containment in the most demanding oil and gas environments:

Frac Pad Liners

Heavy-duty LLDPE liners protect well sites against spills, equipment traffic, and harsh fluids. Designed for rapid installation and long service life.

Produced & Process Water Containment

Secure containment for produced and processed water. Textured liner options provide slope stability and long-term performance.

Drilling Mud Containment

Abrasion-resistant geomembranes for mud pits and cuttings. Reinforced details prevent leaks in high-stress zones.

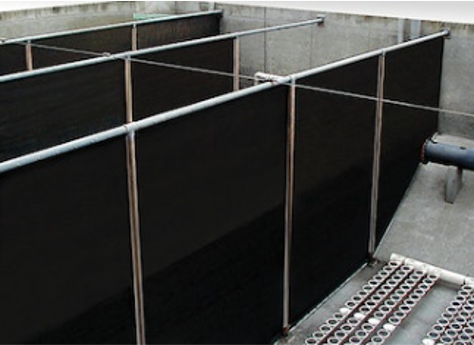

Tank Liners

Drop-in fabricated liners for steel and wood tanks offer fast installs and reliable protection for wastewater, produced water, or process fluids.

Noise Abatement (MLV Add-On)

Mass Loaded Vinyl (MLV) adds a dense barrier for noise abatement around well sites on populated areas..

Why These Factors Matter

✔ Long-Term Containment – Reduces failures, protects infrastructure

✔ Compliance & Liability Control – Meets regulations and minimizes risk

✔ Efficiency & Cost Control – Keeps schedules and budgets on track

✔ Customization & Support – Built for collaboration and performance

Key Differentiators

Key differentiators of E Squared EIA geomembrane product over their competition:

E Squared EIA geomembranes are engineered with a proprietary blend of high-quality materials, offering superior strength, flexibility, and chemical resistance compared to conventional geomembranes.

E Squared EIA geomembranes are designed to withstand harsh environmental conditions, including UV exposure, extreme temperatures, and chemical exposure, ensuring long-term performance and reliability.

E Squared offers tailored geomembrane solutions to meet specific project requirements, including thickness options, material compositions, and custom sizing, providing flexibility and optimization for various applications.

E Squared employs state-of-the-art seaming techniques to ensure strong and reliable connections between geomembrane panels, minimizing the risk of leaks and enhancing overall system integrity.

E Squared geomembranes undergo rigorous testing and certification processes to meet industry standards and regulatory requirements, providing assurance of performance, safety, and environmental compliance.

E Squared is committed to sustainability and environmental stewardship, utilizing eco-friendly manufacturing processes and materials, and offering geomembrane options that support water conservation and resource management initiatives.

E Squared provides comprehensive installation support, including technical assistance, training, and guidance from experienced professionals, ensuring proper installation and maximizing the effectiveness of the geomembrane system.

E Squared has a proven track record of successful geomembrane installations in a wide range of potable water applications, demonstrating reliability, performance, and customer satisfaction over time.

These key differentiators set E Squared EIA geomembranes apart from the competition, offering unmatched quality, performance, and support for potable water projects.

Application Products

Products Used In This Application

Our materials are made in the USA and fully BABAA-compliant. Each product is manufactured and fabricated with performance, durability, and efficiency in mind.

XTRM Ply™ PVC Geomembrane

- Flexible, weldable, and ideal for fast deployment

- Strong chemical resistance and UV stability

- Proven in applications such as lagoons and liners

ERCoat™ EIA (1000 & 7087 Series)

- Exceptional puncture resistance and tear strength

- Ideal for baffle curtains and steel tank linings

- Advanced resistance to stress cracking and chemical degradation

- Available with NSF approvals

- 120” Width available

Flex-Pipe CIPP

- TPU and TPO Coated felts for lateral and mainline applications

- Widths from 65” to 116” available

- TPU nylon reinforced products for use as expansion bladders

- Suitable for traditional and UV curing methods

Flexliner™ LLDPE

- High tensile strength and dimensional stability

- Outstanding flexibility for conforming to subgrade movement

- Excellent impact and puncture resistance

- Fish Grade with 20 year warranty available

- OIT Grade with 20 year warranty available

- Industrial Grade for Oil & Gas applications