Modular construction traces its roots back to the 1670s, but it truly gained momentum in the United States following World War II. At that time, it provided a quick and cost-effective solution for housing returning veterans and laborers. While traditionally applied to residential and low-rise structures, this construction method has evolved. Today, it’s making its way into high-rise developments—and more recently, into geosynthetic applications, especially with geomembrane systems, where it brings notable benefits in both cost and quality.

Key Topics:

- Factory-Fabricated Geomembranes and Modular Construction

- Comparing Costs: Factory vs. Field Fabrication

- Consult a Geomembrane Specialist

- Core Benefits of Factory Fabrication

- Eco-Friendly Construction Practices

Factory-Fabricated Geomembranes: Modular Construction in Action

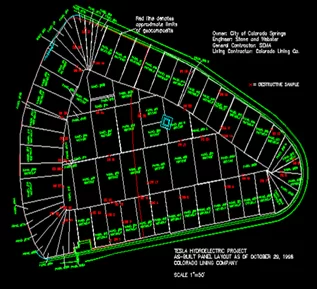

Geomembranes have embraced a modular construction approach through factory fabrication. In this context, “modular” means creating individual sections of a project in a controlled manufacturing environment, then assembling those components on site. This method, common in items like roof trusses, tilt-up concrete walls, and pre-assembled bathrooms, now offers similar benefits for geomembrane installations.

Factory vs. Field Fabricated Geomembranes: A Cost Perspective

The Fabricated Geomembrane Institute (FGI) has developed a spreadsheet tool that helps users compare the estimated costs of installing geomembranes fabricated in a factory versus those constructed on site. This calculator also considers the quality improvements associated with factory fabrication. It’s available for free download here:

https://www.fabricatedgeomembrane.com/protected/pond-liner-calculator

Note: The calculator does not factor in the cost of materials like the geomembrane itself. It is intended strictly for rough estimation purposes—each project should still undergo a formal cost assessment. The tool can also be applied to other geosynthetics, such as factory-made geotextiles.

Why Factory Fabrication Stands Out

One of the standout benefits of factory fabrication is the ability to produce panels with complex shapes and geometries in a controlled setting. This is far more efficient than attempting to custom cut and assemble irregular shapes or varying slope angles on site, especially under unpredictable weather conditions.

Additionally, accessories like pipe boots, ballast tubes, vents, and other customized components can be pre-assembled in the factory. This drastically reduces field labor and ensures superior seam quality. Factory environments also allow for the use of specialized welding techniques, such as dielectric welding, which are not practical in the field due to equipment size and power needs.

Moreover, manufacturers can implement purpose-built jigs and fixtures that enhance the speed and precision of production—translating into significant cost savings for the project owner.

A Sustainable Alternative

Factory fabrication of geosynthetics supports sustainability by reducing the carbon footprint associated with installation. Up to 85% of geomembrane welding can be completed using electricity, often derived from renewable or low-emission sources, rather than relying on fossil fuels typically used for on-site fabrication.