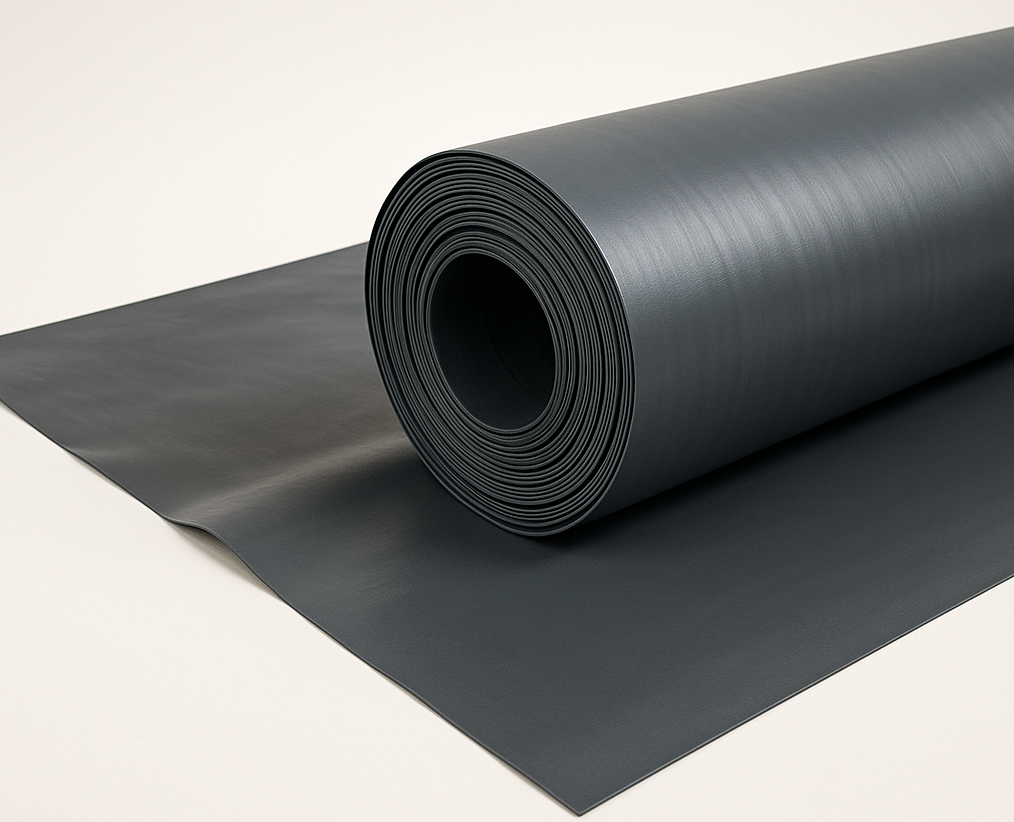

Specification-Ready: PVC Geomembranes for Modular Liner and Cover Systems

For your next containment or cover project, consider PVC geomembranes that are tested and certified to published standards as a reliable and cost-effective solution for civil and geotechnical applications.

Specification Benefits

PVC panels are factory-fabricated up to 40,000 ft², reducing field seams and installation time while minimizing leak risks up to 80%. Their flexibility allows them to conform to uneven terrain without extensive subgrade preparation, outperforming PE in flexibility tests. PVC geomembranes formulated for chemical and UV resistance offer durable performance for over 20 years in exposed environments. Both solvent and thermal welding techniques are supported for seam integrity. Studies show PVC can deliver up to 30–40% total cost savings when factoring material, construction, and CQA costs.

Modular Construction Benefits

Modular PVC geomembranes use large, pre-welded panels tailored to project specs, enabling quick deployment and consistent quality through automated factory fabrication and ISO QA/QC protocols. This method reduces on-site labor, destructive testing, avoidable repairs, and installation errors, and adapts to complex geometries with custom shapes and anchor options—ideal for scalable, repeatable construction.

Environmental Stress Crack Resistance

PVC geomembranes exhibit exceptional resistance to environmental stress cracking (ESC), a failure mode common in more rigid polymers like HDPE. Unlike crystalline materials that are prone to brittle fracture under sustained stress and chemical exposure, PVC’s amorphous structure and plasticizer-enhanced flexibility allow it to absorb strain without crack propagation. This makes PVC ideal for long-term containment in chemically aggressive environments, including leachate ponds, industrial lagoons, and secondary containment systems where ESC risk is elevated.

Proven Legacy in Environmental Protection

PVC geomembranes have been successfully deployed for over five decades in critical environmental containment applications. Their track record includes municipal solid waste landfills, Superfund sites, agricultural lagoons, and stormwater basins. Recognized by EPA, USDA NRCS, and ASTM standards, PVC liners have consistently demonstrated long-term durability, chemical resistance, and low permeability. Their legacy performance in both buried and exposed conditions reinforces their role as a trusted barrier material for environmental protection and regulatory compliance.

PVC Geomembrane Applications

PVC geomembranes have played a critical role in non-hazardous landfill operations for decades, offering proven performance across every phase of containment. From temporary daily covers and interim caps to primary liners and final closure systems, PVC’s flexibility, chemical resistance, and long-term durability have made it a preferred material for municipal solid waste (MSW) facilities. Its use extends to leachate pond liners and stormwater diversion structures, where its low permeability and ease of fabrication support regulatory compliance and operational efficiency. This legacy of success underscores PVC’s value as a versatile, specification-ready solution for containment and cover uses. Other applications include:

| Application Type | Description |

|---|---|

| Waste Piles (covers) | Surface barrier to reduce infiltration and erosion |

| Landfill Caps/Liners (Subtitle D) | Composite liner systems for municipal solid waste |

| Stormwater/Wastewater Containment | Basins, impoundments, and diversion structures |

| Stormwater/Wastewater Containment | Basins, impoundments, and diversion structures |

| Leachate Ponds & Waste Lagoons | Chemical-resistant containment for aggressive liquids |

| Secondary Containment | Spill prevention for tanks and chemical storage areas |

| Aquaculture/Irrigation Channels | Flexible lining for water conveyance and fish production |

| Drinking Water Storage Basins | Low-permeability liners for potable water reservoirs |

| Equalization (EQ) Basins | Flow balancing and surge containment in treatment systems |

| PFAS-Impacted Soil and Water Containment | Engineered barriers for emerging contaminant isolation |

| Biosolids Drying Beds and Storage | Cells Odor and leachate control for organic residuals |

| Industrial Process Water Basins | Corrosion-resistant lining for manufacturing and utility operations |

| Mining Heap Leach Pads and Tailings Ponds | Acid- and metal-resistant containment for extractive industries |

| Agricultural Waste Lagoons and Transfer Systems | USDA-compliant liners for manure and nutrient management |

| Anaerobic Digester Covers | Gas-tight covers for biogas capture and odor control |

| Evaporation Ponds | Solar-driven concentration of brine and industrial effluent |

| Decorative and Recreational Ponds | Flexible liners for landscaping and water features |

| Salt Brine and Deicing Fluid Containment | Seasonal storage for DOT and municipal operations |

| Temporary Bypass or Emergency Storage | Cells Rapid-deploy containment for system outages or overflow |

| Floating Covers for Odor and Algae Control | Surface barriers for open water bodies |

| Vertical Wall Liners for Tank Retrofits | Interior lining for steel or concrete containment structures |

PVC geomembranes that meet ASTM D7176, D7177, D7408, USDA NRCS 594, FGI 1120, EPA RCRA, and EPA/600/R-93/182 standards, that are offered in reinforced/non-reinforced types, and available in various thicknesses, integrated with anchoring and ballasting that are properly designed for the application have proven to be an effective solution.

PVC Geomembranes Standards

| Standard | Issuing Body | Acceptance of PVC Geomembranes | Functional Role in Specification | Application Context |

|---|---|---|---|---|

| ASTM D7176 | ASTM International | Explicitly defines physical property requirements for PVC geomembranes | Establishes baseline mechanical properties for new, non-reinforced PVC materials | Buried containment systems |

| ASTM D7408 | ASTM International | Accepts PVC geomembranes for seam testing | Specifies minimum shear and peel strength for PVC seams in containment use | Seamed containment installations |

| FGI 1120 | Fabricated Geomembrane Institute (FGI) | Benchmarks PVC geomembrane performance | Provides performancemetrics for evaluating new, non-reinforced PVC geomembranes | General performance guidance |

| USDA NRCS 594 | USDA NRCS | Lists PVC geomembranes as acceptable liner material | Recognizes PVC as a compliant liner for agricultural waste transfer systems | Waste transfer systems |

| EPA/600/R93/182 | U.S. EPA | Includes PVC geomembranes among approved liner types | Guides QA/QC protocols for waste containment liners, including PVC | Waste containment and environmental protection |

| RCRA Subtitle D | U.S. EPA | Accepts flexible membrane liners including PVC for nonhazardous waste sites | Requires composite liner systems; PVC geomembranes often serve as the FML component | Municipal solid waste landfills (non-hazardous) |

E Squared Technical Textiles, a U.S. Company, headquartered in Hillside, New Jersey, has been manufacturing PVC geomembranes for over 40 years, and is ready to support your needs with specifications, product samples, draft submittals, test data, plan layouts and details to help you streamline design, reduce risk, meet duration and performance requirements and maximize value on your next project.